DPF error

AdBlue error

DEF error

EGR error

MERCEDES DIESEL PARTICULATE FILTER REPLACEMENT COST

Mercedes diesel particulate filter replacement cost: do you really need new hardware?

For many Mercedes owners, the first shock is not the warning on the dash, but the estimate for a diesel particulate filter replacement. The filter is an expensive emissions part, and the cost to replace it can grow quickly once labour, sensors and diagnostics are added. On larger vehicles and sprinter vans the numbers climb even higher, especially if a mechanic suggests additional filters, a catalytic converter, or other exhaust products at the same visit. Our approach is different: we sell an electronic reset kit that clears persistent display content after the real problem is fixed, so your vehicle can keep moving without automatic assumptions that new hardware is required.

Why DPF warnings appear and stay

Modern diesel engine management tracks particulate loading, exhaust temperature and sensor feedback. If values drift, the system may limit performance or trigger limp mode to protect your vehicle. Even after proper work is done, the dash can still show fault content related to your dpf filter simply because historic data was never cleared.

- Short urban trips that prevent diesel particulate filter cleaning from completing.

- A sensor that briefly misread temperature or pressure, then returned to normal.

- A workshop attempt to force a dpf regeneration that ended early.

- Aftermarket wiring or parts fitted and later removed, leaving old codes behind.

Cleaning vs replacement: what drives costs

Before accepting the highest price on the list, it helps to understand the options. In many cases, professional dpf cleaning is enough: a cleaning service removes ash and soot from the particulate filter, checks flow and temperature response, and returns the part to serviceable condition. Regular maintenance and correct driving patterns can keep costs down by allowing automatic filter cleaning to complete instead of interrupting it.

Replacement becomes necessary when the filter substrate is cracked, heavily melted or physically blocked. That is when the cost to replace the unit, including extra work around seized bolts or rusted flanges, can become a top line item on the invoice. Some owners look at aftermarket parts to reduce price, while others stay with the original manufacturer for peace of mind. In both cases, the control unit still needs a proper reset so it recognises the new condition instead of reporting what it saw before the work was carried out.

Where our reset kit fits into the picture

We do not sell filters, converters or any physical hardware. Our single product is an advanced electronic kit that clears non-critical DPF and sensor codes once the real cause has been addressed. It works after diesel particulate filter cleaning, after professional dpf cleaning, or after a full replacement part has been installed. It does not change maps, does not alter limp mode logic and does not interfere with safety; it simply lets your vehicle show the current state instead of old data.

- Use it after a mechanic has finished filter cleaning and confirmed that sensors and temperatures look good.

- Use it when a new filter has been fitted and the warning light remains because memory was not cleared.

- Use it to quickly confirm that recent work was effective before you agree to more parts or extra costs.

What we sell (and what we deliberately skip)

In our store you will not find shelves of exhaust filters, aftermarket converters or long lists of part numbers. We offer one electronic item with a clear description, sku and price, focused purely on clearing the relevant codes after legitimate work. That means you can skip pressure sales around replacement parts that your vehicle may not need, and decide calmly whether to invest in new hardware based on accurate readings, not on a dashboard that still shows particulate warnings from weeks ago.

Balance between cost and maintenance

Diesel particulate systems are built to last, but they depend on regular maintenance and correct operating temperature to stay effective. By combining sensible driving, timely diesel particulate filter cleaning and a precise electronic reset after service, you can control costs while protecting your vehicle. If inspections reveal that your dpf filter truly needs replacement, that decision will be based on evidence, not guesswork. Until then, a clean dash and correct sensor data are your best tools for knowing what really has to be done—and what can safely wait.

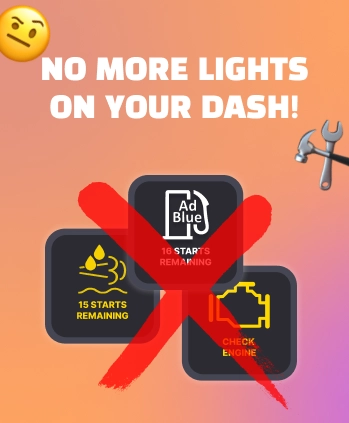

Have you ever seen such lights?

The most common errors

It can program ECU with maximum ease for everyone!

WE OFFER 3 SOLUTIONS

Choose the right solution and install it yourself in a few minutes!

SCR ADBLUE / DEF DELETE

PACKAGE DEAL

ADBLUE (DEF) COUNTER RESET

What you'll run into without our module

Engine: OM642 3,0L. Gain: +40HP, +49 ft-lb

for you

No problem - just tell us which one

is best for you!

While we strive for immediate dispatch, please allow an average of 1-3 days from order placement for delivery.

We are also found by queries

Additional information

In many quotes the word replacement appears early, but a careful inspection of the filter can show that replacement is not always needed. A partially loaded filter may respond well to professional cleaning, turning a planned replacement into a postponed replacement and freeing budget for other work. Only when the filter substrate is cracked, melted or physically broken does a full replacement become the responsible choice, and even then the replacement should follow a clear explanation of why the original filter can no longer be saved.

When estimating replacement intervals, ask the shop to document back-pressure across the filter so you can compare cleaning results with any future replacement. This makes each replacement a data-backed decision instead of an automatic response to a warning light on a filter that might still be recoverable.

In day-to-day conversations with workshops, you will often hear dpf mentioned as if dpf replacement is the only answer whenever a filter warning appears. In reality, a dpf can often be recovered if the filter is sound and the replacement is proposed only because of time pressure or lack of data. Before agreeing to any dpf replacement, ask the shop to show you pre- and post-cleaning figures for the filter so you can compare the cost of cleaning with the cost of a full replacement on paper. This way, the dpf is treated as an asset that can be maintained instead of a disposable filter that always jumps straight to replacement.

Many fleet managers now keep a small log where every dpf event is recorded, with notes on dpf mileage, dpf temperature and the filter condition. When the filter still flows well and pressure is low, they mark the dpf as “serviceable” instead of booking an immediate replacement. That single decision often saves the filter for many more cycles and turns the dpf from a mystery box into a monitored filter component with clear service history.