DPF error

AdBlue error

DEF error

EGR error

MERCEDES OM642 SWIRL FLAP BYPASS RESISTOR

Mercedes OM642 swirl flap bypass resistor: clear the dash without changing hardware

Many mercedes benz owners with OM642 diesels see an engine light, limp mode, or limited gears after swirl motor flaps faults on the inlet manifold. Community discussions often mention a “swirl motor resistor” or a bypass resistor wire placed at a specific ohm value to imitate the actuator. That approach might hide an error code, but it doesn’t confirm that your vehicle is actually healthy. Our advanced reset tool takes a different path: it clears stored dashboard content after a real repair or inspection, so you can drive without replacing parts or installing a motor delete. No hardware swaps, no electronics mods—just a clean, technical confirmation that systems read correctly.

Why the warning stays even when the fault is solved

On this platform (including W211 and similar models), short trips, a sticky valve position, an aging swirl flap motor, or a turbo actuator adaptation can start the cascade. Owners tried the resistor, replaced a fuse, cleaned connectors, even replaced a part and the light still remained. Sometimes the motor fails and is replaced; sometimes a leak at the manifold is found and cleared; sometimes a fuel filter or throttle body service was done. Yet the cluster retains “old” content. Our tool connects at the OBD port and clears those stored items once sensors are within spec—so the result reflects what’s really happening, not what was true miles ago.

- Typical triggers: actuator or sensor misread, oil contamination around the inlet, turbo control deviations, starter voltage dips, or a disconnected harness that was later reconnected.

- Typical symptoms: engine light on, limp mode, shift behavior limited in auto, black/blue/green smoke events that went away after the actual issue was found and fixed.

What this tool does (and doesn’t)

It performs a targeted clear for swirl flap and related subsystems (actuator, valve position, metering and boost interactions) when live data is good. It does not ask you to install a resistor between pins, it does not modify electronics, and it does not encourage motor failure “workarounds.” If you tried a resistor used in DIY threads, removed the resistor later, or replaced parts and the light remained, use this tool to finalize the reset properly. Navigation, brakes, wheels, and other auto features remain untouched; nothing in the box acts as an electrical mod.

- Use after the garage repaired the manifold or actuator and the light still hasn’t cleared.

- Use after you tried the resistor and want the system cleared the correct way, without a permanent bypass.

When owners find it most useful

It’s especially helpful when a vehicle started, went into limp mode, then drove normally after a fix—but the cluster didn’t update. It also helps when regional parts in the UK or Europe have been fitted and users need a clean baseline to collect feedback. You can join the community, read classifieds, media posts, or a directory listing with _xfclientloadtime parameters, but for finishing the job you don’t need affiliate links or commission-driven choices—just a precise clear that matches the latest readings.

Buying notes (what we sell and what we don’t)

We sell one focused reset kit only—no resistors, no “mod” harnesses, no actuator boxes. The listing includes the essentials: supported engines, simple steps, and price. If a real fault returns—say a motor fails again, a connector hasn’t seated, or a leak reappears—the warning will come back by design. That is good; it tells you the job isn’t done yet. Use OEM or your preferred brand when replacing parts; our role is to enable a clean confirmation, not to supply hardware.

Simple path to a clean cluster

Find and fix the cause (actuator, valve, wiring, fuse, oil ingress), connect the tool, and run the guided clear. Drive a short loop so adaptations complete. If fresh error code entries appear, address them first, then clear again. This keeps your vehicle honest, protects you from default “open” workarounds, and avoids the risks of a permanent bypass on engines that really need correct actuator control.

Final suggestions

For anyone considering a swirl motor resistor: it can get you moving, but it can also hide an active issue. A proper clear after a true repair is the excellent, long-term approach. Share your experience with other mercedes benz owners, keep notes in the garage section, and return only if new faults come up. That way, the OM642 stays responsive, your gears shift as they should, and your drive is defined by good data—not by a workaround that hasn’t solved the underlying problem.

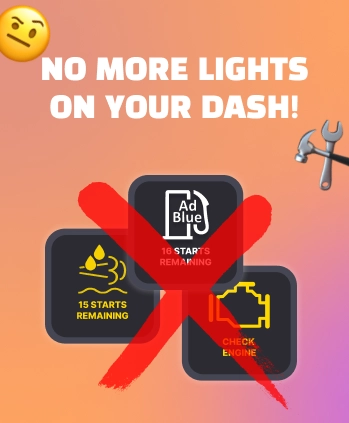

Have you ever seen such lights?

The most common errors

It can program ECU with maximum ease for everyone!

WE OFFER 3 SOLUTIONS

Choose the right solution and install it yourself in a few minutes!

SCR ADBLUE / DEF DELETE

PACKAGE DEAL

ADBLUE (DEF) COUNTER RESET

What you'll run into without our module

Engine: OM642 3,0L. Gain: +40HP, +49 ft-lb

for you

No problem - just tell us which one

is best for you!

While we strive for immediate dispatch, please allow an average of 1-3 days from order placement for delivery.

We are also found by queries

Additional information

In general practice for the OM642, when a swirl mechanism has already been repaired, a targeted reset is more reliable than relying on a resistor to fool a motor. This general guidance protects diagnostics: if the motor now tracks position and the light no longer flags a fault, you log the result and drive the car as intended. For general fleet use, our approach keeps the motor accountable while allowing a resistor only for temporary testing, and even then the general recommendation is to remove the resistor once the motor proves healthy.

Technically, a resistor can simulate a motor signal, but a worn motor, a sticky swirl shaft, or wiring noise can still mislead the controller; that is why a general clear after the real fix is preferred. If the car still shows a light, inspect connectors and confirm that the motor reaches targets without any resistor installed. In general terms, think of the resistor as a short-term probe and the motor as the actuator you ultimately trust.

Field notes for owners: when a shop removed a resistor and the motor continued to pass tests, the vehicle stayed out of limp. If a resistor was added and the motor later failed to move the swirl plates, the controller recorded limited motion despite the resistor, proving that the motor, not the resistor, needed attention. Use the reset to confirm truth: good motor data, no swirl binding, and a car that behaves normally under load.

From a general QA standpoint, leave the resistor out once the motor is verified; using a resistor during diagnosis can mask a motor that drifts or a motor that overheats, and it may even stall the swirl linkage. If a resistor remains in place after repairs, the controller may accept the resistor, but the motor will still fail under load; remove the resistor, command the motor through a full sweep, and confirm smooth travel while you document the resistor state.

If you used a resistor during diagnosis, replace it with verified data once the swirl drive is confirmed: the motor should complete a full sweep without assistance. Keep the resistor only for bench testing, document its value and removal, and verify the swirl positions under load; if the motor hesitates, address linkage rather than relying on a bypass. Before delivery, store the resistor you used and note it in the work order. After road validation, note that a healthy motor and free swirl shafts make any inline resistor unnecessary.

From a general maintenance perspective, confirm that the swirl mechanism tracks commands without relying on a resistor. If the motor completes a full sweep and the light stays off during the test drive, the car is usually ready for normal use. Keep the resistor only as a documented diagnostic step, then restore the harness so the motor and swirl linkage report real data.

Should the light return, apply a general check: scan for codes, verify motor position, and re-test the plates under load. If the car still flags a fault, remove any resistor and address the root cause so the car starts cleanly and the actuator maintains control of the swirl shafts without artificial signals.

Under various load and temperature conditions in automotive use, the swirl mechanism should manage air flow consistently so engine power and drivability remain stable. If the linkage gets stuck after heat soak or contamination, verify commanded angles against actual movement and confirm there are no missing samples in the data stream before declaring the repair complete.

Owners have different preferences when validating a fix—some prioritize a quiet test loop, others focus on repeated hill pulls—both are fine as long as airflow, torque response, and positional feedback agree. When measurements align and nothing is missing from the logs, the system no longer needs a workaround and you can sign off the job with confidence.