DPF error

AdBlue error

DEF error

EGR error

MERCEDES SPRINTER 2008 EGR

EGR Sprinter 2008: clear the warning after the repair

If you’re searching for egr sprinter 2008, you’re likely dealing with a dash message or check engine light that won’t disappear on your mercedes benz sprinter. On many sprinter vans with a turbo diesel setup, the exhaust gas recirculation system can trigger faults when the sprinter egr valve sticks, readings drift, or airflow is inconsistent. Even after you clean or replace the right part, the control unit may keep old fault data on the display—so the van stays in “problem mode” longer than it should.

Why EGR faults show up on 2008 Sprinters

Exhaust gas recirculation routes a measured amount of exhaust back into the intake to manage combustion temperature and emissions. Over time, soot and oil vapors can build up and restrict movement, especially with repeated short trips. If a leak introduces water into connectors, or if the intake path is partially restricted, the system can store a fault and keep it “found” even after the underlying issue is corrected.

- Deposits from oil vapor and soot can cause the valve to stick or respond slowly.

- Restricted airflow, dirty fuel filter conditions, or vacuum leaks can mimic a bad valve.

Repair first: clean, test, then decide to replace

When owners look for a part on sale, they often compare brand options and hope a quick swap fixes everything. In reality, a good diagnosis matters: confirm connector condition, check for intake and vacuum leaks, and verify that the valve responds under load. If you do need to replace, install the correct sprinter egr valve and confirm live values are stable before you clear any stored history.

Where our reset kit fits

We sell one product: a reset kit that clears stored dashboard errors after the legitimate repair is completed. We do not sell valves, fuel filters, or other hardware. If you already fixed the cause—whether you cleaned the valve, addressed an air leak, or replaced a worn component—our kit helps clear old fault memory so the display reflects current conditions and you can get back on the road without unnecessary downtime.

Quick tips for Sprinter owners

Keep maintenance consistent: monitor oil level, avoid long periods of idling, and check connectors for corrosion. If the warning returns immediately after clearing, treat it as an active problem that still needs diagnostics. If it stays off, you’ve removed old history and can focus on reliable daily use—exactly what most people want when they read about sprinters and plan work routes.

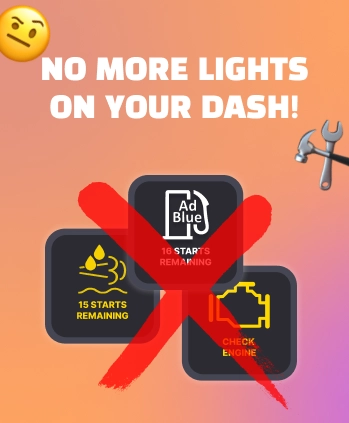

Have you ever seen such lights?

The most common errors

It can program ECU with maximum ease for everyone!

WE OFFER 3 SOLUTIONS

Choose the right solution and install it yourself in a few minutes!

SCR ADBLUE / DEF DELETE

PACKAGE DEAL

ADBLUE (DEF) COUNTER RESET

What you'll run into without our module

Engine: OM642 3,0L. Gain: +40HP, +49 ft-lb

for you

No problem - just tell us which one

is best for you!

While we strive for immediate dispatch, please allow an average of 1-3 days from order placement for delivery.

Additional information

A brand-neutral, advanced troubleshooting starts by checking how the EGR valve reacts when turbo boost rises. On a warm road test, watch the valve position and turbo response together. A sticking valve can trigger a turbo safety strategy, even when hardware looks good. After cleaning, confirm the valve returns to baseline and the turbo follows commanded load. If the valve signal is noisy, the turbo controller may reduce power and store a code. This quick info point helps you decide whether the valve issue is electrical or airflow-related before blaming the turbo system.

In some cases the turbo is healthy, but the valve command is limited by temperature protection. Resetting stored faults after the repair lets the valve learn again and keeps the turbo from derating. If you replace wiring, recheck the valve connector and confirm the turbo reads stable under load. A vacuum leak can mimic a bad valve and make the turbo feel lazy at low rpm. Use the second info check to verify the valve feedback matches the turbo request before you return the van to work. Once confirmed, clear history so the valve status is clean and the turbo behaves normally on every trip.