DPF error

AdBlue error

DEF error

EGR error

MERCEDES SPRINTER DEF INJECTOR

Sprinter DEF injector: why the warning stays on and how to clear it

If you’re searching for sprinter def injector, you may be dealing with a dash light after refilling diesel exhaust fluid or after a repair on a mercedes benz sprinter 2500. The DEF fluid injector is part of the diesel emissions fluid system: it doses diesel exhaust fluid into the diesel exhaust stream so emissions controls can work properly. When something in this chain is out of range, the vehicle can store faults and keep the light on even after the part is replaced.

Common causes of DEF injector-related faults

In real-world use, a sprinter mechanic often sees more than one trigger. Water contamination, freezing conditions, wiring issues, or a clogged injector can all produce the same “injector” message. Some owners buy parts based on price or sale listings, but the brand and fitment matter—and so does confirming the actual failure before ordering anything.

- Contaminated fluid (water mixed in), incorrect fill, or low-quality gallon refills causing poor dosing.

- Heating or cooling problems that affect DEF temperature and dosing stability.

- Electrical faults that make the control unit flag the fluid injector even when the injector is good.

Repair first, then clear stored fault history

After you replace the injector part (or confirm it’s working), the control unit may still show a warning window because stored errors remain in memory. That’s where our reset kit helps: it clears stored dashboard faults once the underlying issue is fixed, letting you keep driving without paying for repeated shop visits and without unnecessary downtime.

What we sell and what we don’t

We sell only one product—a reset kit to remove stored errors from the instrument cluster after legitimate repairs. We do not sell injectors, fuel injector components, or any additional hardware. If your service provider says you “should upgrade” diagnostics, that usually means verifying the repair with live data before clearing codes.

Practical tips for owners and fleets

For fleets watching specials and parts availability, the best savings come from accurate diagnosis and fewer repeat visits. Use good-quality fluid, keep the DEF system protected from contamination, and don’t ignore early warning signs—especially if the van is used in cold climates where heating matters. Once the system is confirmed healthy, clearing stored faults is the final step that gets your vehicle back to work fast.

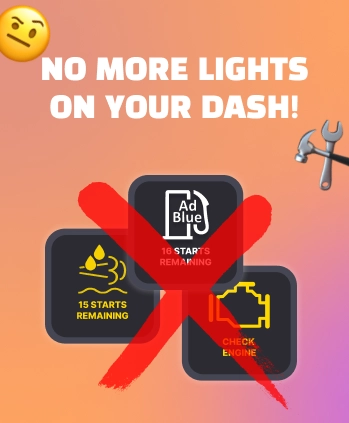

Have you ever seen such lights?

The most common errors

It can program ECU with maximum ease for everyone!

WE OFFER 3 SOLUTIONS

Choose the right solution and install it yourself in a few minutes!

SCR ADBLUE / DEF DELETE

PACKAGE DEAL

ADBLUE (DEF) COUNTER RESET

What you'll run into without our module

Engine: OM642 3,0L. Gain: +40HP, +49 ft-lb

for you

No problem - just tell us which one

is best for you!

While we strive for immediate dispatch, please allow an average of 1-3 days from order placement for delivery.

Additional information

In general, if you need a quick fix without wasting time, focus on diagnosis before buying parts. Many owners start with mini checks—verify wiring, confirm dosing, and inspect connectors—because the wrong part won’t reduce downtime. When comparing brands, look at fitment notes, service history, and one set of reviews from a trusted source; if the system was exposed to water or harsh land conditions, you may see repeat faults until the real cause is corrected.

After the repair, keep a simple record of parts used, the part number installed, and the symptoms that triggered the warning. If the fault returns, it’s often faster to re-check parts connections than to replace parts again. Our kit fits this workflow: once the correct part is in place and the system is stable, it clears stored history so you’re not chasing the same parts message twice.

During colder months, sprinters can be more sensitive to temperature swings, so keep the battery strong, let the system warm up, and watch for a sudden black smoke event that suggests a separate issue. If you need to talk through what was done at the shop, review the work order with your service provider and confirm the right steps were followed.

For fleet teams, a simple board checklist helps: schedule service verification, run service diagnostics, and complete service confirmation after the drive cycle. If the warning persists, book service follow-up, then finish with a final service check once stored history is cleared.

Before you buy anything, collect information from the fault readout, the recent repair notes, and the drive conditions—good information makes decisions faster. If you choose to buy a reset kit, use it only after the service work is confirmed complete; this avoids masking an active problem. Keep the same information on file for the next visit, because service teams can compare history and shorten service time, especially when you buy parts or book follow-up during busy seasons.