DPF error

AdBlue error

DEF error

EGR error

MERCEDES SPRINTER DEF LEVEL SENSOR

If your mercedes sprinter def level sensor starts reporting incorrect readings, the dash can quickly escalate from mild notifications to hard restrictions. On a Mercedes-Benz diesel, one bad sensor signal may trigger warning lights, countdown messages, and reduced operation even when the tank isn’t actually empty.

What the DEF level sensor does on a Mercedes-Benz Sprinter

On a mercedes benz sprinter, the SCR system relies on diesel exhaust fluid data to control emissions and manage nitrogen oxide. The level sensor (often integrated into the tank unit) works together with other sensors and components, including the quality sensor, temperature logic, wiring, and dosing control. When the ECU sees inconsistent values, it can assume the fluid is empty or contaminated, even if your fill level is fine.

Common symptoms and why they happen

A typical sensor failure may be caused by internal tank electronics, connector issues, crystallization, poor fluid, or contamination (even small amounts of water). In cold climates, the heater circuit and air leaks around lines or seals can also contribute. Sometimes, unrelated maintenance problems (like low oil level or a stressed cooling system) can appear alongside SCR issues and confuse the diagnosis.

- Persistent warning lights or “check DEF/SCR” messages, even after refilling

- Dash shows “empty” or a sudden drop in reading, then returns to normal

- Restart countdown / limited starts affecting your vehicle

- Intermittent faults that come and go with temperature or bumps in the road

A practical alternative to replacing parts right away

Replacing the tank part, harness, or multiple components can be expensive and time-consuming—especially if the first repair attempt doesn’t fix the root cause. Our plug-and-play OBD tool is designed for diesel engines in this brand family to remove SCR-related fault messages and restrictions from the dashboard without immediately removing or swapping hardware. This helps the user keep working and avoid downtime while deciding what repair path best fits their needs.

- No need to hunt for products across different brands or wait on backorders from a parts store

- A clear description of the selected script and what it will apply, based on your setup

- Often more predictable than trial-and-error replacement or wholesale “guesswork” repairs

How it works and what to expect

Connect to the OBD port, choose the matching script on the in-car screen (or via microSD option if your setup requires it), wait until the process completes, then disconnect. The goal is to clear the SCR-related warnings and limits tied to the DEF level signal so your vehicle can operate normally again. Pricing (price) depends on the configuration and what you need to apply for your Sprinter’s ECU family.

Note: Emissions-related changes may be intended for off-road or where permitted. The user is responsible for following local rules and requirements for road use.

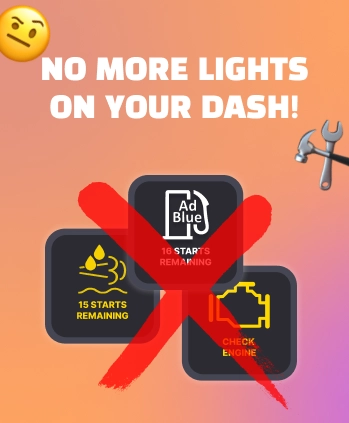

Have you ever seen such lights?

The most common errors

It can program ECU with maximum ease for everyone!

WE OFFER 3 SOLUTIONS

Choose the right solution and install it yourself in a few minutes!

SCR ADBLUE / DEF DELETE

PACKAGE DEAL

ADBLUE (DEF) COUNTER RESET

What you'll run into without our module

Engine: OM642 3,0L. Gain: +40HP, +49 ft-lb

for you

No problem - just tell us which one

is best for you!

While we strive for immediate dispatch, please allow an average of 1-3 days from order placement for delivery.

Additional information

In real-world conditions, a single sensor can report the wrong level and trigger warnings even when the diesel exhaust fluid is correct. When the sensor drifts, the ECU may treat the tank level as empty, and the engine logic can limit starts. A technician may test the sensor signal, inspect equipment connections, and compare the reported level to the actual fill level. If the sensor passes continuity checks but the level value still jumps, the problem can be inside the sensor head or in shared wiring with other parts.

Because nox control depends on stable readings, the control unit may treat any sensor glitch as a critical level event. That is why many owners replace parts one by one—heater parts, pump parts, and sensor parts—yet the same level message returns. If the engine harness has corrosion, the sensor ground can float, and the level can drop to zero under load. In some diesel cases, vibration near the engine mount stresses connectors, so the sensor intermittently misreads level and the ECU flags parts as failed. Swapping parts without confirming the sensor output over time can be costly, especially when the engine is needed daily.

Our OBD solution helps suppress dashboard faults tied to the sensor and level logic, so the engine can keep running while you plan repairs. It is useful when the sensor says level is low but the sensor is clean, the sensor wiring is intact, and the sensor still triggers limits. Instead of ordering parts immediately, you can keep the vehicle mobile, then replace parts later when conditions and shop equipment are ready. Keep an eye on the dash level reading after each refill. For many diesel fleets, a failing sensor can cascade into repeated sensor faults, sensor counters, and sensor driven derates even if the level is correct. If your diesel schedule cannot pause, this approach lets the sensor warnings stay off while you verify which sensor, sensor circuit, or sensor unit is the real cause. Once the engine is stable, you can address the final sensor issue with the right fix.

Our company focuses on a plug-and-play tool that helps reduce dashboard complaints when a sensor misreports level on the SCR side. It targets exhaust warnings where exhaust logic interprets exhaust signals as critical and exhaust restrictions appear. When the sensor value drops, the level reading can jump, and the exhaust counter may start. Repeated exhaust messages may push exhaust limits even if the exhaust hardware is intact. Instead of buying parts immediately, use the tool to keep the vehicle working while you diagnose parts and schedule parts replacement with proper equipment. No extra accessories are required.

If a sensor keeps reporting low level, the tool can clear exhaust faults so the sensor and level strategy stops triggering dash alerts; later you can confirm the sensor wiring and level behavior and replace the final parts if needed, after the exhaust limit resets.