DPF error

AdBlue error

DEF error

EGR error

MERCEDES SPRINTER EGR GASKET

A leaking or incorrectly seated sprinter egr gasket can cause unexpected warning messages, rough running, and repeated fault codes on a Mercedes-Benz diesel van. Even when the issue starts as a small seal problem, it can escalate into drivability limits that keep your vehicle off the road and cost you time.

What the EGR gasket does on a Sprinter

The EGR gasket seals the connection points in the exhaust gas recirculation path so exhaust flow is directed correctly through the valve and related passages. On a mercedes benz sprinter, this seal helps maintain stable pressure and prevents unwanted air leaks that can confuse sensors and control logic. If the gasket fails, hot gases can escape or the system can pull in fresh air, affecting mixture control and triggering faults tied to the EGR valve and flow plausibility.

Common symptoms when the seal is not holding

Depending on the model and mileage, a failing gasket can mimic bigger problems. What looks like a bad valve or clogged passage is sometimes simply a poor seal at the flange near the intake manifold or EGR cooler area. Heat cycling, overtightening, or warped mating surfaces can all contribute. If your cooling system is under stress, temperature swings can make small leaks worse.

- Intermittent warning lights and recurring EGR-related codes after clearing

- Hissing/sooty residue near the EGR connection, plus inconsistent idle

- Reduced power events caused by EGR flow deviations or air leaks

- Issues that appear after service work on the intake manifold or exhaust system

Why replacing parts isn’t always the fastest answer

Many owners search for sprinter parts and end up replacing multiple components—gaskets, sensors, coolers, even the valve—before the fault finally stops. You may see listings like elring egr valve gasket with notes such as “fits mercedes benz,” but real-world fitment can still vary by engine code, year, and emissions configuration. This is especially common across dodge freightliner mercedes generations and trims such as mercedes benz sprinter 2500.

On newer platforms like a 2022 mercedes benz sprinter, even a small sealing issue can trigger strict diagnostics and derate logic. If you can’t afford downtime right now, waiting on parts and repeated disassembly can be a problem.

A practical way to keep your vehicle moving

Our plug-and-play OBD tool is designed to remove EGR-related dashboard errors and restrictions without immediately removing or replacing hardware. That means you can continue using your vehicle while you decide whether to repair the leak, reseal connections, or schedule a full service later. We sell a single solution focused on clearing the warnings and limitations that often appear when the EGR valve and gasket area causes repeated faults.

- Connect to OBD, select the matching script, and wait for completion

- Reduce nuisance warnings tied to exhaust gas recirculation logic

Important notes before you choose a path

If you plan to repair, inspect sealing surfaces around the valve, cooler connections, and intake manifold joints, and confirm there are no cracks or misalignment. Also verify there are no related cooling system leaks that could affect temperature control. Emissions-related modifications may be intended for off-road or where permitted; you are responsible for following local regulations for on-road use.

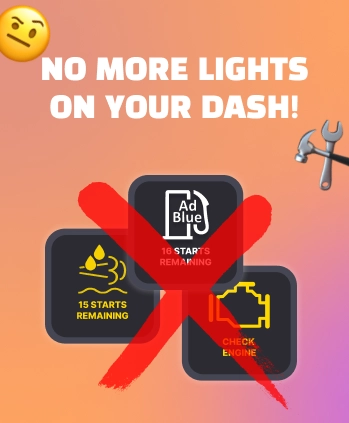

Have you ever seen such lights?

The most common errors

It can program ECU with maximum ease for everyone!

WE OFFER 3 SOLUTIONS

Choose the right solution and install it yourself in a few minutes!

SCR ADBLUE / DEF DELETE

PACKAGE DEAL

ADBLUE (DEF) COUNTER RESET

What you'll run into without our module

Engine: OM642 3,0L. Gain: +40HP, +49 ft-lb

for you

No problem - just tell us which one

is best for you!

While we strive for immediate dispatch, please allow an average of 1-3 days from order placement for delivery.

Additional information

If you need to keep sprinters working while you diagnose the leak point, our tool helps you skip repeated teardown and avoid ordering the wrong part first. A mis-seated gasket can look like a failed valve, but the root cause may be the gasket surface alignment or a small distortion at the center of the flange. Before you rush to a store, confirm the gasket contact area, confirm the gasket is seated evenly, and verify the gasket does not pinch or fold during installation. If the gasket issue returns, you may end up buying the same part again, which leads to more returns and wasted time.

We focus on a single solution rather than accessories, and we offer worldwide shipping with reliable shipping methods. You can checkout online and choose shipping that fits your timeline: shipping with DHL/UPS is typically 2–4 days, and shipping with FedEx is usually 5–8 business days (dispatch commonly takes 1–3 days). The goal is to reduce downtime while you decide which gasket and which part truly needs attention, instead of swapping part after part. If you later decide to repair, the tool helps you keep the vehicle usable while the correct gasket and the correct part are sourced and shipped, without relying on multiple returns due to poor fit.

When a gasket leak forms around the EGR valve on a Mercedes-Benz Sprinter, the gasket seal can trigger faults even if the valve still moves. This gasket issue often looks like failing parts, because the ECU reacts fast and the engine may derate in the engine bay. Our plug-and-play tool helps keep the dash calm while you check parts, confirm the parts list, and plan shipping; fast shipping with shipping tracking reduces downtime, and shipping options cover urgent jobs. If the gasket surface is uneven, replace the gasket and recheck the valve housing and valve path before ordering more parts with a fresh gasket.

For many diesel owners, the gasket between the EGR cooler and the valve flange is the first point to inspect, but the gasket can also fail where the pipe meets the valve. A warped flange can crush the gasket and make parts appear defective, while the engine control treats it as a flow error during engine protection. Instead of buying parts immediately, use our tool to clear limits, then place a parts order and schedule shipping for the correct gasket and a new gasket; we provide shipping updates, shipping choices, and shipping support so shipping stays predictable.

If you manage a fleet, repeated gasket faults can pile up: a gasket that seeps, a gasket that whistles, and a gasket that leaves soot. Even after you replace parts, the ECU may still flag the valve circuit, so the tool helps suppress those warnings while you verify the gasket fit and check parts stock. Worldwide shipping is available, and shipping times can match your schedule with shipping tracking and shipping carriers that fit your route. This approach lets you plan parts timing, avoid rushed parts swaps, and keep the engine running; it’s useful whether you’re dealing with one valve, valve calibration, or multiple valves.