DPF error

AdBlue error

DEF error

EGR error

SCR METERING MODULE

SCR metering: clear dashboard warnings without replacing parts

Seeing stubborn alerts that point to the dosing system on your vehicle? Our compact kit gives a clean, non-invasive way to remove warning content related to SCR dosing so you can keep driving and plan service later if needed. No hardware swaps, no tear-downs—just a focused tool that confirms the current state and switches the light off when the issue has already been addressed in your garage or at a center.

Why SCR dosing warnings persist

After real repairs, the cluster can still hold codes from SCR metering. Typical triggers include a metering line restriction, a metering valve adaptation that never completed, or temperature variance in metering module coolant. Some vehicles also log side codes from a fuel pump or a metering module water pump, even when the part tests fine. You might also see stored notes “from SCR metering module” after a short road test—this is a memory state, not always a fresh failure.

What this tool does (and doesn’t)

The kit connects at the diagnostic port and clears non-critical tags tied to the dosing circuit so the display reflects the real condition of your vehicle. It does not rewrite maps, nor touch automatic or electric subsystems, nor alter any manufacturer safety logic. Think of it as a quick confirm/reset that lets owners drive now and decide on deeper work later if fresh faults return.

- Targets alerts from SCR metering, metering line and metering valve adaptations, and metering module mounted parts.

- Keeps stock hardware in place; no new part purchases required when the fault was already fixed.

When to use it

- After replacing hoses or sensors, but the cluster still shows an item “from scr metering”.

- When a scan tool shows historic dosing codes that block readiness even though the pump and lines pass tests.

- If you need a clean baseline before a longer road run or after a short stop in a busy garage.

Simple sequence

Verify fluid quality and temperatures, check the line and valve connections, then run the kit. Drive a short loop and review the following list: no new warnings, stable temperatures, and normal dosing counts. If fresh codes reappear, that points to a real part concern you can address later with your preferred brand or manufacturer components.

Store details (we sell only this product)

Here you will find one focused item in our products catalog—this product is a clearing kit for dosing-system alerts. The description below states exactly what’s included, the model categories it supports, and the price. Inventory is limited by design; returns follow our general policy. We do not sell pumps, lines, or other parts; the aim is to help your vehicle show an accurate status so you can choose the right repair path later if needed.

Notes and reminders

The kit does not “fix” hardware. If a pump, line, or valve truly fails, fresh warnings will come back—that’s expected. Use the tool to clear stale memory after repairs, to validate a model-specific drive cycle, or to confirm that the issue is gone before you consider more work. If a new alert points to a metering module water pump or metering module coolant temperature that’s out of range, schedule follow-up with your chosen brand or manufacturer parts and re-check with a scan tool.

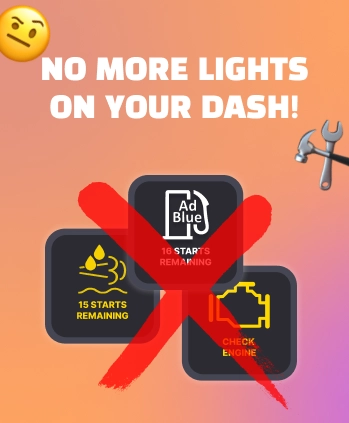

Have you ever seen such lights?

The most common errors

It can program ECU with maximum ease for everyone!

WE OFFER 3 SOLUTIONS

Choose the right solution and install it yourself in a few minutes!

SCR ADBLUE / DEF DELETE

PACKAGE DEAL

ADBLUE (DEF) COUNTER RESET

What you'll run into without our module

Engine: OM642 3,0L. Gain: +40HP, +49 ft-lb

for you

No problem - just tell us which one

is best for you!

While we strive for immediate dispatch, please allow an average of 1-3 days from order placement for delivery.

We are also found by queries

Additional information

Under real-world conditions, fleets need clarity before signing off on repairs. Our reset process verifies metering logic and confirms that related parts respond correctly without disturbing the engine. When conditions vary—cold starts, short trips, heavy loads—the metering counters can retain memory even after parts test fine; clearing the cluster helps isolate the true signal. It is a practical way to check metering dosing results across identical routes and compare how parts behave under the same conditions.

If fault codes return only in extreme conditions, document the conditions and rerun a short loop to validate metering stability. Replace no parts unless new data demands it; instead, compare metering values before and after service and note whether specific parts, hoses, or sensors correlate with the change. In most cases the metering system proves consistent once the display is clean, the engine warms properly, and operating conditions are steady; that is the moment to decide which parts, if any, should be ordered. Keep a record of parts on hand and parts previously changed; avoid mixing parts from different batches during tests.